Aircraftsmen Of Georgia for Dummies

Table of ContentsA Biased View of Aircraftsmen Of GeorgiaWhat Does Aircraftsmen Of Georgia Mean?Aircraftsmen Of Georgia - QuestionsThe Only Guide to Aircraftsmen Of GeorgiaLittle Known Facts About Aircraftsmen Of Georgia.What Does Aircraftsmen Of Georgia Do?

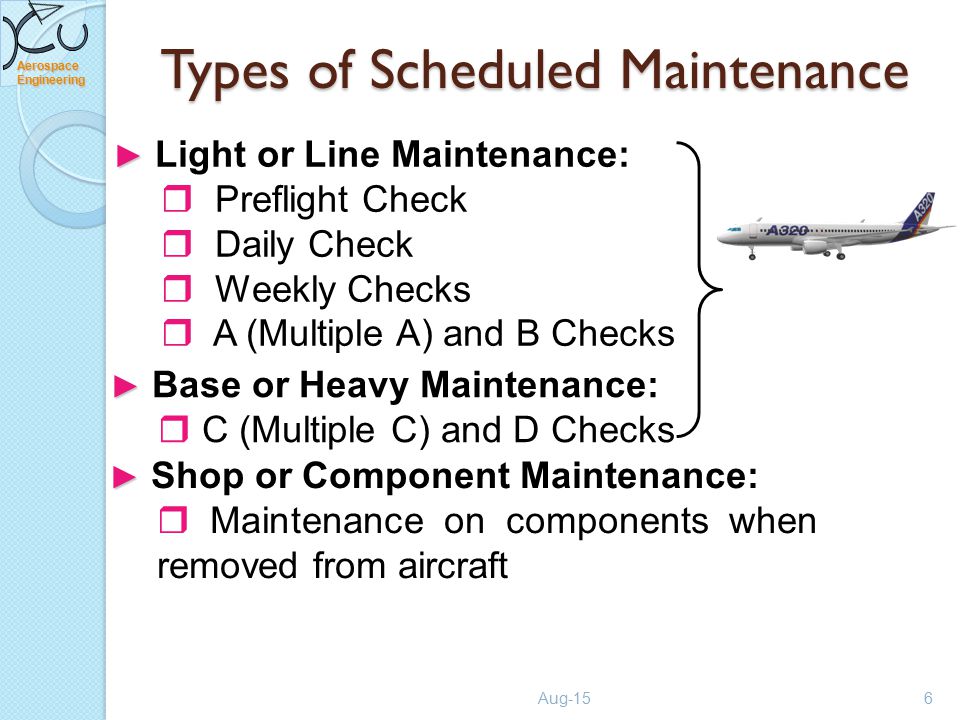

The air travel industry is very managed, indicating that airlines and also other business airline business need to exercise constant examination programs developed by aeronautics authorities - Aircraft Manufacturers. In the United States, aircraft upkeep programs are looked after by the Federal Aviation Management (FAA). The FAA needs each airline/operator to establish a Continuous Airworthiness Maintenance Program (CAMP). https://aircraftsmenofgeorgia34032.bloggactivo.com/.Checks are essential to continually do as they keep aircraft secure as well as airworthy. Having such a rigorous maintenance program guarantees that travelers will obtain to their destinations securely on an aircraft that has been fully vetted for any kind of concerns prior to leaving the airport terminal entrance! While the FAA manages the guidelines as well as programs, it depends on the real airline company or operator to make certain that maintenance obtains done and also approximately CAMP specs.

The objective of these checks is to conduct both regular as well as non-routine upkeep of the airplane. The upkeep consists of setting up the fixing of well-known issues; changing products after a certain air time, the number of cycles or schedule time; fixing problems found previously, and doing set up fixings. All airplane are different and might need upkeep checks at different times than others.

Aircraftsmen Of Georgia for Dummies

Aircraft require line upkeep every 24 to 60 hours of accumulated flight time, yet it depends on the operator of the aircraft! The following level of checks is understood as A checks. The A check is executed around every 400-600 flight hours, or every 200300 flights, depending on airplane kind.

Often, this maintenance is done overnight as to not interrupt the routine that airline companies keep. The frequency of this check differs by aircraft kind, the trip cycle matter, or the variety of hrs flown because the last check. The upkeep work during A checks often covers general assessments of the inside and the airplane hull for evidence of damages, contortion, deterioration, missing components.

Aircraftsmen Of Georgia for Beginners

Various other work carried out can require things such as: checking emergency lights lubing nose gear retract actuator examining car park brake collector pressure Next, B checks are usually completed during the A check phase, as airlines and operators have terminated B checks. For airlines and operators to successfully maintain, fix, and upgrade an airplane, some B check jobs have been taken in right into A check stages.

Air travel upkeep specialists do B maintenance checks approximately every 6-8 months. It takes around 160-180 labor hrs, depending on the airplane, and also can be finished within 13 days at a flight terminal hangar. Normal work finished during B checks are jobs such as examining alignment and torquing of the nose touchdown equipment limelight or examining the wheel well hydraulic tubing for condition, corrosion, and fluid leakage - Aircraft Inspection.

The C check needs an aviation upkeep technician to perform a deep my link assessment of a bulk of the airplane's parts. The C upkeep check can usually take the airplane out of solution for 12 weeks. This kind of check frequently requires an airplane to remain at a maintenance center for the essential space/tools/maintenance professional functioning hours/materials.

The Ultimate Guide To Aircraftsmen Of Georgia

Air travel maintenance technicians will do specific jobs during C checks, such as: evaluation of structures (load-bearing elements on the body as well as wings) and features for corrosion and also damage checking the procedure of the DC bus tie control unit in-depth lubrication of all installations as well as cable televisions There are various degrees of C checks depending on the kind of airplane, just like just how A checks integrate B check jobs! As an example, a timetable might have air travel maintenance specialists performing C1 check jobs on a certain day and then the next day continuing with C2 and more.

D checks are detailed maintenances of the whole aircraft as well as can mean taking apart the aircraft to examine for damages and also rust. The procedure can take upwards of 30,000 to 50,000 labor hours over a duration of four to six weeks. With the whole airplane stripped down as well as devices got rid of, airline companies commonly make a decision to recondition aircrafts' insides and also upgrade them altogether during D checks.

Oh, and the cost of the entire procedure can set you back upwards of a few million bucks! There comes a certain factor where airline companies realize that the price of repair service is greater than the real expense of the airplane. This usually happens after two or 3 D checks. There is a rigorous system for aircraft to be effectively maintained, fixed, upgraded, and also examined as time takes place.

Getting The Aircraftsmen Of Georgia To Work

Train to come to be an air travel upkeep professional in as little as 14 months at National Aeronautics Academy! Submit the type listed below to start!.

This area describes common fixings of the major architectural components of an airplane. When repairing a harmed component or part, consult the suitable area of the producer's SRM for the aircraft. Usually, a comparable repair is illustrated, and the types of product, rivets, and also rivet spacing as well as the methods and procedures to be used are noted.

Top Guidelines Of Aircraftsmen Of Georgia

If the needed details is not discovered in the SRM, attempt to find a similar repair service or setting up mounted by the manufacturer of the aircraft. To maintain the float in an airworthy problem, regular as well as constant evaluations must be made because of the rapidity of corrosion on metal parts, especially when the airplane is run in seawater.